In today’s competitive industrial landscape, PET bottle recycling has evolved from a basic environmental initiative into a high-stakes race for material purity. As global FMCG giants enforce rigorous zero-plastic mandates, the market’s focus has shifted: the challenge is no longer finding buyers, but ensuring the output meets the uncompromising standards of brands like Coca-Cola or Unilever. This is why a high-performance pet recycling machine is no longer just equipment—it is a strategic asset. Success in this sector requires an engineering-first approach that can transform "messy" post-consumer waste into high-purity, food-grade rPET. By leveraging smart, closed-loop systems, plant owners can minimize their carbon footprint while maximizing the market value of every flake produced.

PET Recycling Machine Workflow: Engineering for High-Purity Flakes

The technical core of a PET recycling machine lies in its ability to separate PET from what it is not—the adhesives, PVC labels, and residual organic liquids. If you have managed complex or hazardous waste streams before, such as Chemical Drum Recycling: How to Safely and Efficiently Recycle Industrial HDPE Barrels, you know that even minor chemical contamination can ruin an entire batch. While PET is lighter and more brittle than HDPE, the principles of deep decontamination remain similar. Understanding How HDPE Recycling Machines Handle Complex Waste Like Chemical Drums provides valuable insights into the heavy-duty washing and filtration required for industrial-grade purity.

-

Smart NIR Sorting

This is your first line of defense. Advanced PET recycling machines utilize Near-Infrared (NIR) sensors to eject PVC and non-PET materials before they enter the crushing stage. -

Precision Shredding

Maintaining a consistent flake size (12-14mm) while minimizing "fines" (dust) is essential. High dust levels represent material loss and can clog downstream filtration systems. -

High-Intensity Hot Washing

It takes a precise balance of temperature, friction, and chemicals to strip away label adhesives without damaging the PET polymer itself. -

Extrusion & SSP Decontamination

For those targeting the premium market, a Solid State Polycondensation (SSP) reactor is non-negotiable. It is the only way to restore Intrinsic Viscosity (IV) and ensure the pellets are chemically safe for food.

PET Recycling Machine Tiers: Choosing Between Textile and Food Grade

A recurring question from procurement managers is: "Which pet recycling machine is truly the best for my specific facility?" The honest answer is that it depends entirely on your end-buyer’s requirements. There is no point in investing in an expensive food-grade SSP reactor if your target is exclusively the polyester fiber market. However, to ensure long-term flexibility, many investors look at Advanced Plastic Recycling Production Lines: 3 Ways to Enhance Value from Complex Waste to understand how modularity can help them pivot as market demands shift.

-

The Textile/Fiber Market

This route prioritizes high-volume throughput and efficient physical washing. It is a stable, reliable market for clothing, carpets, and strapping materials. -

The Food-Grade (Bottle-to-Bottle) Market

This is where the highest margins are found. Beverage brands demand rPET that matches the clarity and chemical safety of virgin plastic, requiring much higher engineering standards and rigorous decontamination technologies.

PET Bottle Recycling ROI: Analyzing Costs and Operational Efficiency

Investing in PET bottle recycling is a major capital commitment. Our industry experience shows that the "cheapest" equipment quotes often end up being the most expensive due to frequent downtime and high energy consumption. For mid-sized entrants, starting with a Plastic Recycling Line for Small & Mid‑Size Plants: Scalable Solutions, Lower OPEX is often the smartest strategic move to lower operational expenses (OPEX) while stabilizing your raw material supply chain.

-

Energy Management

Energy consumption is often the biggest killer of profit. Modern PET recycling machine systems with closed-loop water filtration and high-efficiency motors can slash running costs by up to 30%. -

Automation Efficiency

A fully automated PLC interface allows a single operator to manage a high-capacity line, significantly reducing labor overhead and human error.

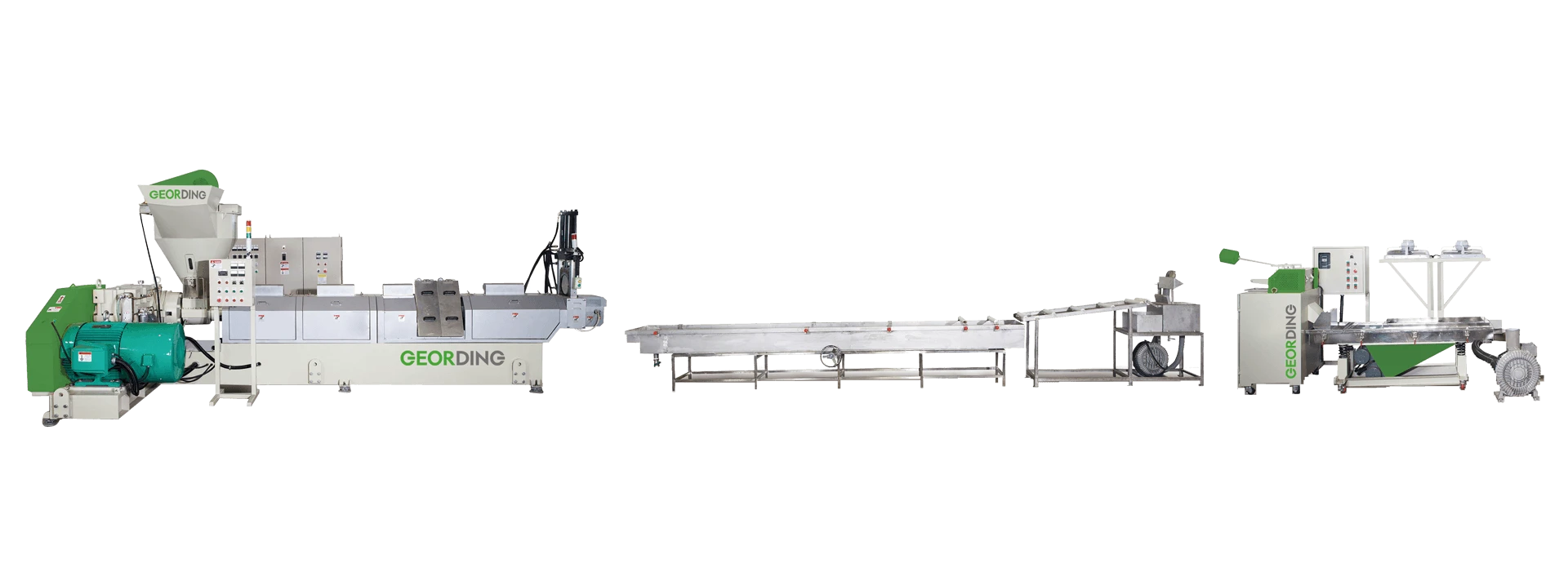

PET Recycling Machine Solution: Force Feeding & Spaghetti Cutting Excellence

To achieve high-efficiency pelletizing from PET flakes, we recommend the Force Feeding Single Stage Spaghetti Cutting Recycling Pelletizing Machine. Unlike standard gravity-fed systems, this pet recycling machine is specifically engineered to handle light, bulky PET flakes with precision.

-

Force-Feeding Efficiency

The integrated force feeder overcomes the "bridge-building" issue common with PET flakes, ensuring a consistent, high-pressure flow into the extruder. This results in 15-20% higher throughput compared to traditional feeding methods. -

Single-Stage Simplicity

By streamlining the process into a high-performance single stage, we reduce the thermal history of the polymer, preserving the material's physical properties while lowering energy consumption. -

Spaghetti (Strand) Cutting Precision

This method provides excellent cooling for PET strands before pelletizing, resulting in uniform, high-quality pellets that are favored by secondary processors for spinning or molding. -

Custom Screw Design

Our in-house designed screws are specifically tuned for the unique melt-viscosity of PET, ensuring stable extrusion pressure and a consistent output.

(Full panorama of a GEORDING industrial PET bottle recycling production line featuring silos, control panels, and extrusion systems.)

(Extruded recycled plastic strands emerging from the die and entering a water cooling bath for the spaghetti-cutting pelletizing process.)

PET Bottle Recycling Standards: Meeting FDA, EFSA, and GRS Requirements

In the global PET bottle recycling market, certifications are your "license to operate." Without an FDA or EFSA LNO (Letter of No Objection), global beverage brands simply cannot purchase your resin. Our engineering team doesn't just deliver hardware; we deliver an audit-ready process. We guide you through the "challenge tests" required for food-grade safety, making sure your PET recycling machine investment actually pays off in the high-premium global market. Furthermore, GRS (Global Recycled Standard) certification ensures that your output is traceable, which is a mandatory requirement for fashion and textile brands today.

Partner with Experts in PET Bottle Recycling

The PET bottle recycling sector is evolving rapidly. Whether you are looking to upgrade an existing line or build a new food-grade facility, the right engineering is the only thing that separates a profitable plant from a maintenance nightmare.

Want to see how our Force Feeding Single Stage system can optimize your production? Our technical consultants are ready to provide straight answers based on real-world data and localized market conditions. Contact us today for a professional consultation, and let’s turn your plastic waste into a high-value industrial resource.