Recently, one of the most frequently discussed topics across industrial clusters is this: the EU Carbon Border Adjustment Mechanism (CBAM) will begin charging fees in 2026, and domestic carbon fees are also imminent. For traditional industries such as textiles, cement, and steel, carbon emissions have shifted from an environmental textbook issue to a very real cost pressure reflected directly on the profit and loss statement.

As energy price volatility combines with rising carbon costs, business owners are increasingly focused on a critical question: how can companies reduce carbon emissions in the most practical way, with the fastest return on investment, without compromising production capacity or process stability?

Among the many available options, SRF Solid Recovered Fuel (SRF) has emerged as one of the most practical and immediately deployable solutions for industrial transformation, thanks to its technological maturity and flexible implementation.

Carbon Fees are No Longer Just Pressure, But an Opportunity to Rethink Cost Structures

In the past, energy costs were evaluated primarily through electricity prices and fuel costs. Today, carbon emissions themselves have effectively become another form of energy expense that must be carefully managed.

If factories continue to rely heavily on coal, they will not only face steadily increasing carbon fees, but also risk losing competitiveness in the EU market due to excessive product carbon footprints. This is why more and more companies are proactively re-evaluating their energy structures and seeking optimization strategies.

Why SRF Can Serve as a Corporate “Loss-Control Tool”

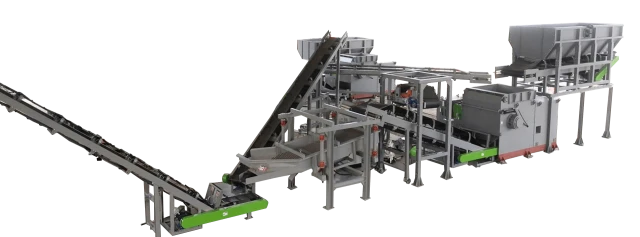

Simply put, the value of SRF lies in “turning waste into energy.” It converts waste materials—previously requiring disposal costs—into a stable, high-calorific alternative fuel.

When high-quality SRF is introduced under regulatory compliance, companies can realize three tangible benefits:

- Immediate loss control: Reduces overall carbon intensity and mitigates profit erosion once carbon fees are implemented.

- Greater access to orders: Improves product carbon data, allowing products to carry a built-in “green pass” and more easily enter international supply chains.

- Risk diversification: Establishes a diversified energy structure, reducing dependence on a single fuel source and exposure to price volatility.

If you would like to better understand how SRF technology addresses real-world challenges related to stability and fuel quality, we invite you to read “The Next Wave of Green Competitiveness: Solving RDF/SRF Challenges—Geording’s One-Stop Solution.”

Why Geording Is a Trusted Partner for Energy Transition

We often share this insight with our clients: the key to successful SRF implementation is not what equipment you purchase, but whether fuel quality can remain stable over the long term. If fuel quality fluctuates, the damage is not limited to equipment—it directly disrupts production rhythm.

Geording provides a controllable, verifiable, and sustainable energy system:

- Coal-like stability: Through core pelletizing and homogenization technologies, SRF maintains consistent calorific performance, ensuring uninterrupted boiler operation.

- Let data speak for you: Systematic operational data directly supports ESG teams in calculating carbon reduction coefficients, making carbon reporting simpler and more transparent.

- Leave maintenance concerns to us: High-wear-resistant systems designed specifically for industrial waste characteristics ensure that maintenance costs do not rise alongside carbon reduction efforts.

About SRF Carbon Reduction: The Honest Questions You Really Want Answered

Q1: What is the biggest risk when introducing SRF?

Frankly speaking, the risk is not whether it can be burned, but whether it can be properly managed. If fuel quality fluctuates, it can indeed affect boiler operation. That is why we recommend not purchasing standalone equipment, but instead adopting a complete management solution. Integrated planning from pre-treatment to feeding systems is the key to uninterrupted operation.

Q2: Is my boiler really suitable for switching to SRF?

This depends on your boiler type and operating habits. In most cases, we recommend co-firing. Typically, only partial adjustments to the feeding control system are required—there is no need for major modifications to the boiler itself. We conduct a technical assessment first and then provide the most practical recommendations.

Q3: How long does it take for this investment to pay back?

This depends on substitution ratios and waste sources. In medium- to large-scale industrial applications, when factoring in both fuel cost savings and avoided carbon fees, most cases see results within 2–3 years. More importantly, this is an investment that acts as insurance for the next decade.

Moving Toward Net Zero: Transforming Carbon Burden into Competitive Advantage

Under the global push toward net-zero emissions, the question for companies is no longer whether to act, but how to act in the most efficient way. Introducing SRF Solid Recovered Fuel is not only about responding to carbon fees—it is about building a stable technical foundation within a circular economy framework.

With extensive experience in turnkey system integration, Geording understands that every factory operates under different conditions. We do not simply sell equipment; we aim to be the technical backbone that supports you throughout your energy transition journey.

If you are standing at a crossroads in your transformation process, feel free to talk with Geording. We will provide a grounded, site-specific analysis tailored to your actual operating conditions.