Waste recycling equipment is entering a new era of intelligence and sustainability. As industries move into 2026 and beyond, ESG goals and circular economy principles are rapidly reshaping global manufacturing. One major trend leading this transformation is the rise of smart and closed-loop waste recycling systems — technologies that redefine how businesses achieve sustainability, efficiency, and measurable ESG performance.

This article explores how next-generation waste recycling equipment enables companies to reduce waste, lower emissions, and turn sustainability goals into tangible value — with practical insights from industry leader Geording.

Trend 1: Why Closed-Loop Waste Recycling Equipment Is Central to ESG and the Circular Economy

To understand the foundation of closed-loop systems, it’s essential to see how scalable recycling infrastructure supports both small and mid-sized operations.As global industries accelerate toward ESG and carbon neutrality, closed-loop waste recycling equipment has become a defining principle of sustainable manufacturing.

Unlike traditional open-loop recycling — where recovered materials are downcycled or repurposed for lower-value uses — closed-loop systems allow materials to be collected, processed, and reused within the same production cycle, minimizing waste and dependence on virgin resources.

For manufacturers and municipalities alike, achieving a closed loop isn’t just about compliance — it’s a strategic advantage for efficiency, resource conservation, and environmental accountability.

Open-Loop vs. Closed-Loop Recycling: Key Differences

| Aspect | Open-Loop Recycling | Closed-Loop Recycling |

|---|---|---|

| Material Flow | Recycled materials are downcycled into lower-value products. | Materials are reused within the same production cycle. |

| Product Quality | Quality and performance gradually degrade after each recycling stage. | Material integrity is maintained or restored through optimized processing. |

| Energy Consumption | Typically higher due to multiple reprocessing steps. | Lower, as materials circulate efficiently in a closed system. |

| ESG & Circular Economy Value | Limited contribution to ESG metrics and resource conservation. | Strong alignment with ESG goals and circular economy principles. |

| Example | Plastic bottles recycled into textile fibers. | Plastic bottles recycled into new plastic bottles. |

Trend 2: Overcoming Complex Waste Challenges with Advanced Recycling Equipment

Despite growing awareness, many recycling facilities still face significant challenges when processing complex or multi-layer waste materials, such as:

- Paper–plastic–aluminum composites (e.g., beverage cartons and food packaging)

- Mixed household waste containing both organic and inorganic components

- Industrial waste streams with variable composition and moisture levels — including HDPE chemical drums, one of the most challenging forms of industrial plastic waste to recycle. For detailed engineering insights into how specialized machinery addresses this issue, learn more in How HDPE Recycling Machines Handle Complex Waste Like Chemical Drums.

Traditional recycling systems often rely on granulation and remelting, consuming large amounts of energy and degrading material quality. To address these challenges, advanced waste recycling equipment now incorporates smart process control and customized thermal-mechanical solutions capable of efficiently separating complex materials.

For a deeper dive into how cutting-edge systems handle complex and contaminated waste, explore our guide on Advanced Plastic Recycling Production Lines.

Trend 3: Smart Waste Recycling Equipment Driving ESG-Aligned Innovation

Smart waste recycling equipment integrates AI-based material detection, PLC automation, and energy recovery systems — allowing factories to close the recycling loop and meet ESG reporting standards.

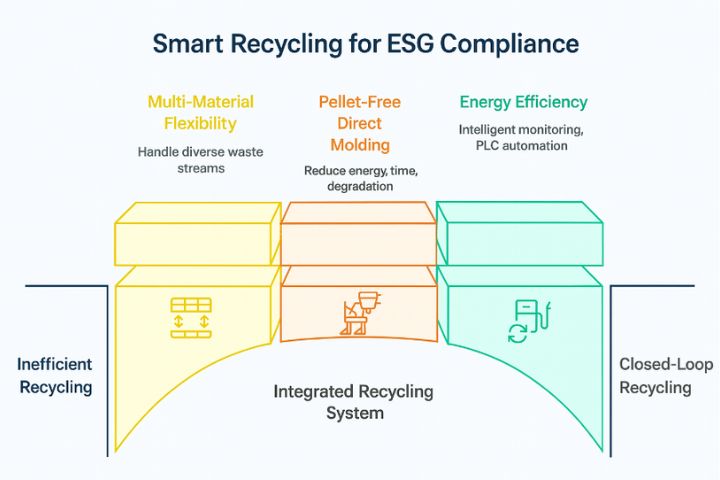

Geording’s R&D team focuses on integrated, intelligent recycling systems designed to meet the demands of modern closed-loop operations. Its solutions are built around three innovation pillars : multi-material flexibility, direct molding, and energy efficiency.

As part of its long-term sustainability commitment, Geording has also been internationally recognized by the Energy Efficiency Movement for excellence in energy-saving design and sustainable manufacturing.

- Multi-Material Flexibility – Tailored systems handle diverse inputs such as composites and household waste, using precise mechanical separation and automated control.

- Pellet-Free Direct Molding – This breakthrough technology eliminates the traditional granulation step, allowing recycled materials to be directly molded or extruded into new products.This trend toward direct recycling reduces energy consumption, processing time, and material degradation — making sustainability more economically viable.

- Energy Efficiency and Smart Control – As part of the smart waste recycling equipment trend, Geording integrates intelligent monitoring, PLC automation, and energy recovery mechanisms. These features enhance performance transparency and align perfectly with ESG reporting requirements.

These smart and energy-efficient systems are redefining how recycling plants achieve closed-loop performance, automation efficiency, and ESG compliance across industries.

Real-World Applications — How Smart Waste Recycling Equipment Drives ESG Success

To illustrate how these trends take shape in practice, several real-world projects demonstrate how smart and closed-loop waste recycling equipment delivers measurable ESG results.

Case Study 1: Government Household Waste Processing Project

Geording collaborated with a municipal waste treatment facility to modernize operations. By introducing a customized household waste recycling system, the plant achieved:

- Over 30% reduction in energy use

- Improved sorting accuracy for mixed materials

- Enhanced safety and maintenance performance

Case Study 2: Japanese Pulp & Aluminum Packaging Recycling

In Japan, Geording helped a packaging company recycle multi-layer beverage cartons containing paper, plastic, and aluminum.Through a bespoke separation and direct molding system, the client successfully recovered reusable pulp fibers and aluminum flakes — turning complex waste into valuable raw materials while minimizing landfill.

These real-world examples reinforce a growing global trend:

Waste recycling equipment is evolving beyond conventional processing — it’s becoming an intelligent ESG enabler that turns sustainability into measurable value.

Trend 4: Waste Recycling Equipment as a Strategic ESG Investment

Implementing closed-loop recycling is no longer a technical upgrade — it’s a strategic ESG investment.Modern waste recycling equipment empowers manufacturers to:

- Reduce operational and energy costs

- Strengthen brand reputation and regulatory readiness

- Contribute directly to circular economy goals

Incorporating such systems allows organizations to turn environmental responsibility into measurable business value — a growing trend among forward-looking manufacturers.

Trend 5: The Future of Waste Recycling Equipment — Intelligent, Integrated, and Sustainable

Looking ahead to 2026, the future of waste recycling equipment lies not in volume, but in intelligence, integration, and closed-loop efficiency. With advancements like smart automation, pellet-free molding, and energy-optimized designs, companies such as Geording are setting the standard for the next generation of ESG-aligned recycling solutions.

As 2026 unfolds, one thing is clear : Smart and closed-loop waste recycling equipment will continue to lead the sustainability revolution — transforming waste management into a core driver of industrial innovation.

From Trends to Action: Best Recycling Machines for Plastic Waste and Circular Systems

As the 2026 trends in waste recycling equipment highlight the growing importance of intelligent and closed-loop systems, organizations are now looking for practical solutions to turn these concepts into reality.

Geording Machinery provides a comprehensive range of modular and customizable recycling solutions engineered to support diverse materials, production scales, and ESG targets.

1. Plastic Recycling and Pelletizing Line

A fully integrated system covering crushing → washing → drying → pelletizing.Ideal for polyethylene (PE), polypropylene (PP), PET, and mixed plastic waste.

2. Compounding Systems

Designed for advanced compound applications, Geording’s compounding systems are engineered to handle diverse formulations — including CaCO₃ filler blends, as well as polymers such as EVA, TPR, PVC, rubber, and other elastomers.

These systems utilize twin-screw extruders integrated with a precision powder weighing module, ensuring accurate dosing, superior mixing performance, and consistent pellet quality. The result is a streamlined compounding and pelletizing process that boosts productivity, reduces material waste, and delivers high-efficiency output for large-scale production.

Whether you’re processing filler-reinforced plastics for sustainable applications or specialized elastomer compounds, Geording’s compounding technology provides precise control and stability — enabling manufacturers to achieve reliable results with every batch.

3. RDF-5 / SRF Pelletizing Equipment

Converts industrial or household solid waste into Refuse-Derived Fuel (RDF). Helps factories turn waste into energy while achieving both economic and environmental benefits.

4. Sheet Extrusion Lines

Enables recycled plastic to be directly formed into sheets or boards — suitable for packaging, construction, and product manufacturing.

5. Custom Turnkey Projects

Geording offers plant-wide planning services — from layout design to after-sales support. Clients can request fully customized systems tailored for complex recycling demands.

To help you better understand how smart and closed-loop waste recycling systems can benefit your operation, here are some of the most frequently asked questions from our clients.

Smart & Closed-Loop Waste Recycling Systems: Top FAQs for 2026 Sustainability Trends

Q1: What is the difference between open-loop and closed-loop recycling systems?

Open-loop recycling repurposes materials into lower-value applications, while closed-loop recycling allows materials to be reused within the same production cycle — reducing waste and virgin material consumption.

Q2: How does smart recycling equipment improve ESG performance?

Smart recycling systems integrate automation, data monitoring, and energy optimization, enabling measurable reductions in energy consumption, carbon emissions, and waste — all of which contribute to ESG compliance.

Q3: Which industries can benefit from closed-loop recycling systems?

Industries such as packaging, manufacturing, construction, and municipal waste management can all implement closed-loop recycling systems to achieve resource efficiency and sustainability goals.

Q4: What is pellet-free recycling, and why is it important?

Pellet-free recycling eliminates the traditional granulation stage by molding recycled materials directly into new products. This process minimizes energy use and material degradation.

Q5: How can I select the right waste recycling equipment for my facility?

Evaluate based on material types, output requirements, energy efficiency, and integration with existing production lines. Consulting an experienced manufacturer like Geording ensures optimal customization for your ESG targets.

Ready to make your recycling system smarter and more sustainable? Contact Geording’s engineering team for a personalized consultation and discover how our closed-loop solutions can help you achieve your ESG goals.

(GEORDING at K Show 2025 – Dusseldorf, Germany

At Hall 12, Booth 12C02-15, GEORDING participated in K Show 2025 (October 8–15, 2025) to highlight Taiwan’s leadership in smart and closed-loop recycling system development.)